As technology advances, the methods for maintaining and inspecting the integrity of materials have evolved dramatically. Non-destructive testing (NDT) is a cornerstone of industrial safety and efficiency, and thermography in particular, has become an invaluable tool. With Airbus at the forefront of these advancements, we explore how Airbus thermography is reshaping modern industrial NDT.

Understanding Non-Destructive Testing (NDT)

Non-destructive testing (NDT) is a technological marvel that offers an efficient means of inspecting and evaluating the properties of materials, components, or assemblies without altering their future usability. The primary essence of NDT lies in its ability to reveal hidden imperfections, thereby arresting potential issues before they manifest into larger problems. While NDT includes a broad array of techniques, each differing in methodologies and applications, the underlying principle remains constant: uncovering defects while preserving integrity. By not compromising the tested components, NDT finds a natural fit across industries where safety, quality, and reliability are paramount. From ensuring the structural soundness of skyscrapers to maintaining the seamless operation of aerospace components, NDT fortifies operational longevity and trust.

Whether used in advanced manufacturing environments or to assess the safety of critical infrastructure, NDT provides a non-invasive lens into a component’s life. It’s about efficiency and future-proofing, preventing disruptions that would otherwise arise if components had to be replaced due to undetected faults. Practical applications of NDT methods enlighten us on its adaptive usage, where these robust mechanisms of inquiry are part and parcel of forward-thinking maintenance and condition monitoring programs. Visual inspection, ultrasonics, and radiography have become the workhorse of modern factories, evolving from merely detecting the obvious to anticipating the unexpected. Through these cutting-edge applications, industries can avoid costly downtimes and elongate the lifecycle of irreplaceable assets.

The Emergence of Thermography in NDT

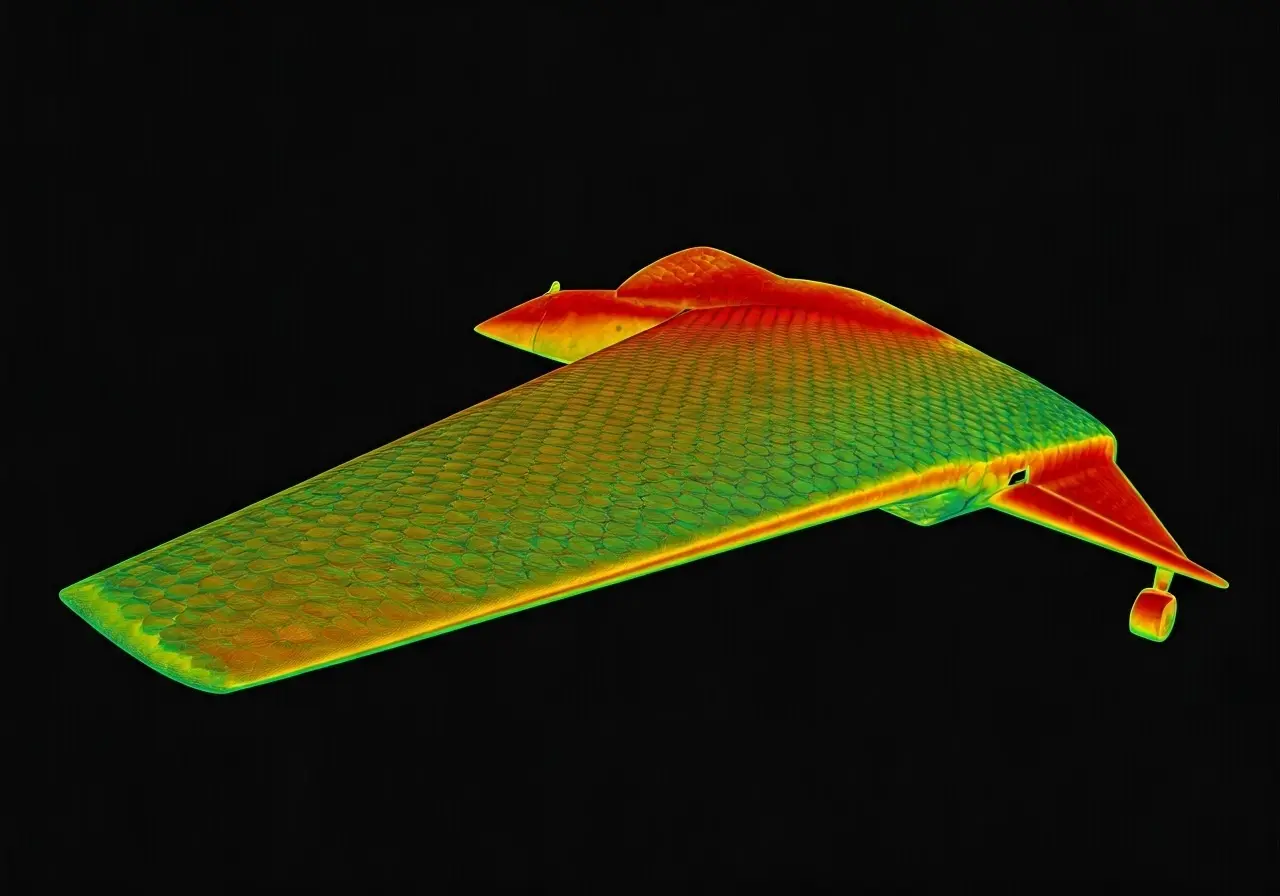

At the heart of modern NDT lies thermography, a revolutionary infrared imaging technique that aids in detecting subtle thermal anomalies. These anomalies often act as signposts indicating irregularities beneath the material surface. Unlike traditional methods, thermography capitalizes on heat differences, offering a non-intrusive peek into the unseen. This is particularly useful in identifying defects like insulation deficiencies or delaminations in materials, where conventional methods might falter. The finesse of thermography arises from its ability to capture these temperature variances effortlessly, thereby ensuring that the integrity of critical components remains unblemished.

Industries ranging from aerospace to construction have adopted thermographic techniques for their precise, reliable, and efficient non-contact inspections. Its application transcends boundaries, offering impeccable data quality essential for further analysis. As infrared sensors become more sophisticated, the capability of thermography continues to expand, allowing industries to delve deeper into their structural assessments. This innovative adaptation of thermal imaging provides an essential toolkit, proactively preventing catastrophic failures by leveraging the smallest deviations in thermal emission.

Airbus’ Contribution to Thermographic Technologies

Through robust research and development, Airbus has significantly propelled the thermographic sector of NDT to unprecedented heights. By focusing on aerospace and defense, where every micron counts, Airbus has refined and expanded the capabilities of thermography. Their pursuits have resulted in systems that not only deliver precision but also scale for big data applications, facilitating rapid processing and analysis. Advanced thermographic systems from Airbus are not just limited to identifying defects; they predict them, thanks to smart integration with predictive maintenance frameworks. This foresight is instrumental for sectors where time and safety are inseparable.

Airbus’ impact can be felt across various industries where their thermographic solutions enhance structural health monitoring. This is particularly evident in aerospace applications, where Airbus’ contribution to thermography has enabled swift inspections without the need for disassembly, thus reducing ground time significantly. Their proactive technologies have been beneficial in both commercial aviation and military domains, where every second and every millimeter of accuracy counts.

Advantages of Airbus Thermography in Industrial Applications

The swift detection abilities of Airbus thermography provide industries with predominance in maintaining their infrastructure. The advantages are manifold: instantaneous data acquisition, real-time monitoring, and an unparalleled ability to spot defects. It’s not just about efficiency but also advancing into a realm where predictive maintenance methodologies become the norm. This sophisticated approach results in significant cost savings obtained from fewer forced outages and decreased maintenance times. As a result, industries witness heightened safety, diminished risk exposure, and above all, sustained productivity.

Importantly, Airbus thermography transcends mere functionality. By offering the luxury of flexibility and precision, it has gained a foothold in sectors where downtime can cost millions. The ability to identify latent issues before they escalate is a consequential advantage, providing organizations with the intelligence to act decisively. This proactive stance has transformed it into a pivotal component of the industrial toolkit, empowering decision-makers to confidently steer their operations toward sustained efficiency.

Real-World Applications and Case Studies

The practicable advantages of Airbus thermography come to life through compelling case studies that underscore its efficacy. For instance, in the energy sector, advancements have empowered engineers to monitor and mitigate thermal inefficiencies in turbine blades. This naturally extends the lifecycle of these expensive assets. Automotive industries benefit equally, with thermography aiding in stress analysis and material evaluations at a nuanced level. Where safety and reliability are concerned, premier aerospace corporations have integrated Airbus solutions to overhaul their inspection protocols, thus enhancing the overall performance of both existing and newly built fleets.

The accumulated evidence underscores an unwavering trend: the amplification of operational efficiency, safety standards, and cost savings through Airbus-developed thermographic technologies. By providing a window into non-visible worlds, these tools offer unparalleled insights, transforming insights into actionable strategies. In effect, organizations can exploit these insights to reinforce their structural integrity, paving the way for sustainable growth and fulfilling the promise of a safer tomorrow.

Future Prospects of Thermography in NDT

The trajectory of thermographic applications in NDT appears destined to ascend even further. Advancements in imaging technology portend an era where artificial intelligence and machine learning models could collaborate with thermographic systems to enhance decision-making processes. These new paradigms will not only optimize defect detection but will also predict potential weaknesses, enabling a proactive approach that could redefine maintenance strategies. Such possibilities provide an exciting frontier for Airbus thermography, whereby industries can address challenges with foresight and precision, transforming how safety and quality assurance are perceived.

In this context, companies like Airbus remain at the vanguard, pursuing relentless innovation to assure their customers of unparalleled inspection standards. The role of thermography will undoubtedly expand, bringing new opportunities to fields such as smart infrastructure monitoring and automated industrial processes. As more industries become aware of its capabilities, the demand for thermographic technology will continuously rise, further solidifying its stature as a quintessential element in the fabric of NDT.

Revolutionizing NDT with Airbus Thermography

Airbus thermography has revolutionized the practice of NDT by introducing highly effective, precise, and cost-efficient methods for material inspection. As industry professionals navigate the complexities of modern industrial needs, the advancements in thermographic technology are ensuring safer and more reliable structures across the globe.