Shear Wave Ultrasonics is a crucial technology used in aviation to detect flaws and cracks in metal parts, preventing potential failures and ensuring safe operations. Shear Wave Ultrasonics are specifically required for inspections of the fuselage and other structural components of aircraft, landing gear, engine components, and weld integrity.

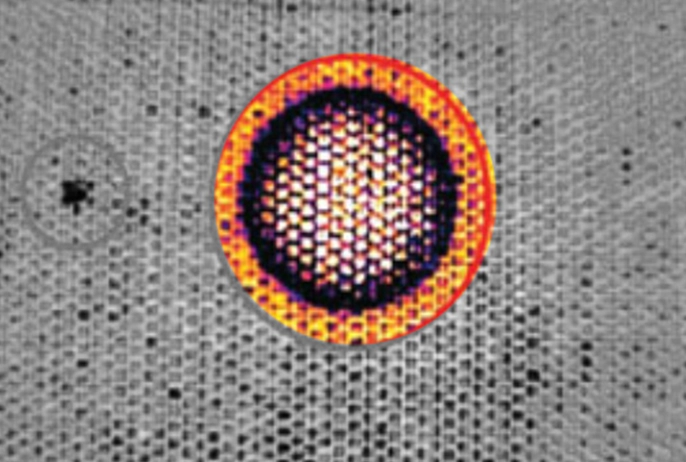

PAUT Ultrasonics is a non-destructive testing technique that is widely used in the aerospace sector for inspecting various critical components and structures of an aircraft. Some of the specific inspections that often require the use of PAUT include fuselage lap joint inspection, composite material inspection, engine component inspection, wing spar inspection, and landing gear inspection.

Ultrasonic thickness measuring is a non-destructive testing technique that is commonly used in the aerospace sector for detecting remaining thickness, corrosion, and lamination discontinuities in critical components and structures of an aircraft.

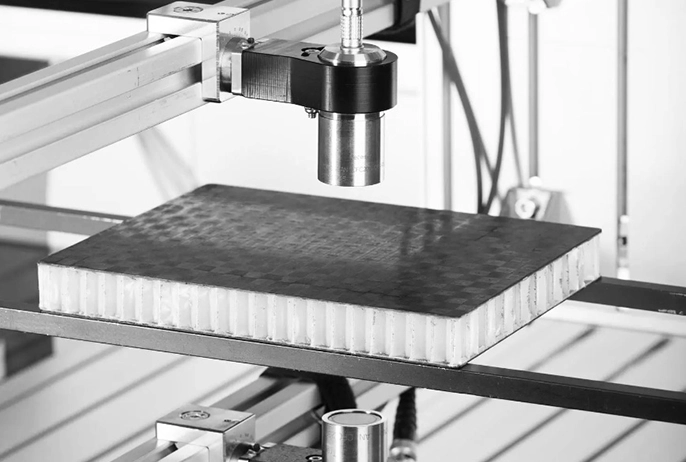

Ultrasonic Bond Testing is a non-destructive testing technique commonly used in the aerospace sector to detect defects in composite structures, which are becoming increasingly prevalent in the manufacture of airplanes and other critical components.

Air coupled ultrasonic inspection is a non-destructive testing technique that uses ultrasonic waves to inspect the interior of aircraft components, without the need for a liquid coupling medium. This technique involves emitting ultrasonic waves into the air, which are then directed into the component being inspected. The waves then either bounce back and are detected by a sensor or travel through the component to a receiving sensor on the opposite side.

High Frequency Eddy Current (HFEC) is the most commonly used inspection technique in the aerospace sector, known for its ability to reliably detect and verify surface defects in aircraft structures and skins.

Low Frequency Eddy Current (LFEC) is a technically challenging inspection technique used in the aerospace sector, often requiring specialized aircraft-specific tooling to inspect multi layer stack ups and detect subsurface flaws when access to the backside of a component is not possible.

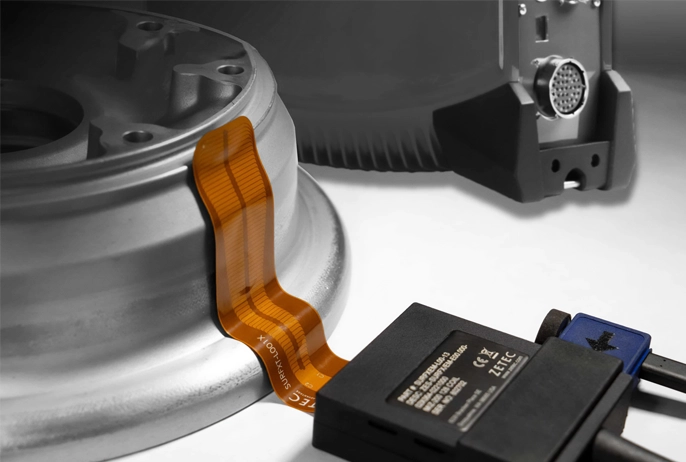

Phased Array Eddy Current is a cutting-edge inspection technique that is particularly useful for inspecting complex geometries, such as the curvature of aircraft components or the complex shapes of engine parts, to detect surface and subsurface defects, such as cracks or corrosion, with a high degree of accuracy and reliability.

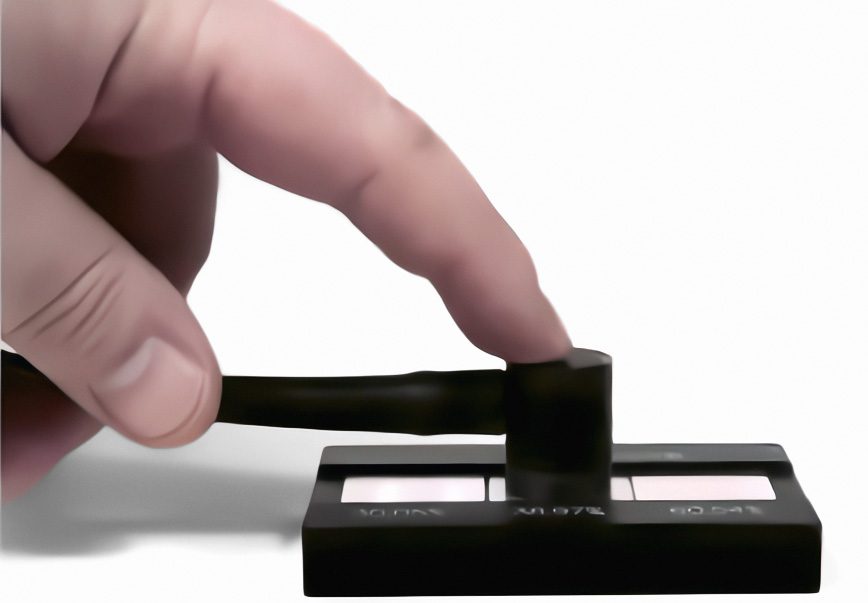

Rotary Open Hole Eddy Current is an inspection technique used in the aerospace sector to detect defects inside fastener holes while the fastener is removed, making it a highly effective method for ensuring the integrity of critical components and structures.

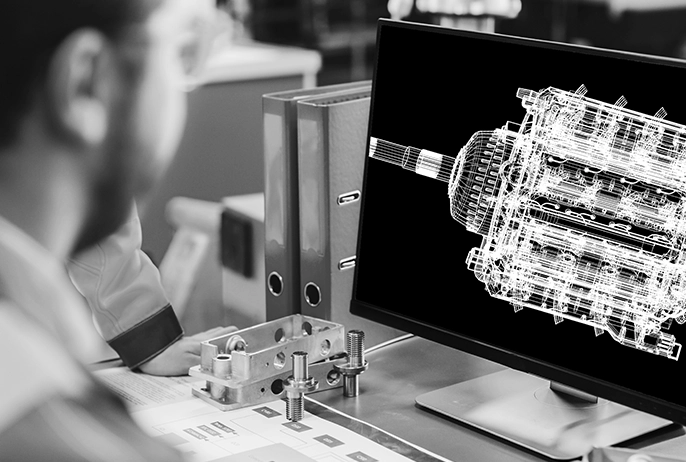

Conventional (Film) Radiography is a widely used inspection technique in the aviation sector for detecting subsurface defects and irregularities in critical components and structures, such as aircraft engines, fuselages, and wings, and is particularly useful in situations where the thickness of a material or the complexity of a component make it challenging to use other inspection techniques.

Computed Radiography is an advanced inspection technique that has gained popularity in the aviation sector due to its ability to quickly and accurately produce digital images of components and structures. This technique uses reusable imaging plates and a scanner to obtain a high-quality, digital image, making it a highly efficient and cost-effective option for inspecting critical components and structures in the aerospace industry.

Computed Radiography is an advanced inspection technique that has gained popularity in the aviation sector due to its ability to quickly and accurately produce digital images of components and structures. This technique uses reusable imaging plates and a scanner to obtain a high-quality, digital image, making it a highly efficient and cost-effective option for inspecting critical components and structures in the aerospace industry.

A Portable AC/DC Yoke is a highly effective inspection tool used in the aviation industry for Magnetic Particle inspections, a non-destructive testing method used to detect surface and slightly subsurface defects in ferromagnetic materials. This portable inspection tool generates a magnetic field that reveals any surface or slightly subsurface defects.

A large magnetic particle bench, such as ones made by Magnaflux, is a versatile inspection tool used in the aviation industry to magnetize components with longitudinal and circular magnetism. This advanced inspection tool generates a magnetic field to reveal surface and slightly subsurface defects in ferromagnetic materials.

Ultra high sensitivity penetrant is an advanced inspection technique used in the aerospace sector to detect the smallest possible surface defects in critical components, such as engine blades and other complex structures. This highly specialized penetrant technique is capable of detecting even the tiniest flaws and discontinuities.

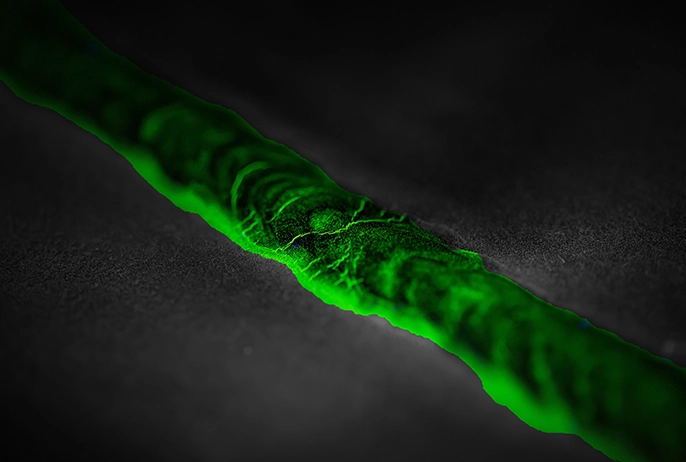

Fluorescent penetrant is commonly used in the aerospace sector to detect surface defects in critical components and structures that are not visible to the naked eye, such as microcracks and other discontinuities, in components such as landing gear components, structures and hardware, to ensure the safety and reliability of modern aircraft.

Thermography is an advanced inspection technique used to detect flaws and defects in new composite structures on aircraft, such as the Airbus A220, by using infrared imaging to detect changes in temperature that may indicate areas of damage or stress. This non-destructive testing method is highly effective at detecting defects in composite structures.

This technique uses a high-intensity light source to rapidly heat the surface of the component, and an infrared camera to detect changes in temperature that may indicate areas of damage or stress. Pulsed Thermography is particularly effective at detecting hidden defects in composite structures, and is a valuable tool for ensuring the safety and reliability of modern aircraft.

Hardness testing is a commonly used inspection technique in the aerospace sector for assessing the mechanical properties of critical components and structures, such as aircraft engine parts, landing gear, and fasteners. This inspection method involves using specialized tools, such as the UCI and Leeb rebound testers, to measure the hardness of materials and detect any areas of excessive wear or stress that may compromise the integrity of the component.

X-ray fluorescence (XRF) works by exposing a material to a high-energy beam of X-rays, which causes the atoms in the material to emit fluorescent X-rays. The energies of these X-rays are characteristic of the elements present in the material, allowing XRF to identify the chemical composition of the material.

By measuring changes in the electrical conductivity of the material, inspectors can determine whether the material has been damaged by heat, which is a common cause of failure in aerospace components.

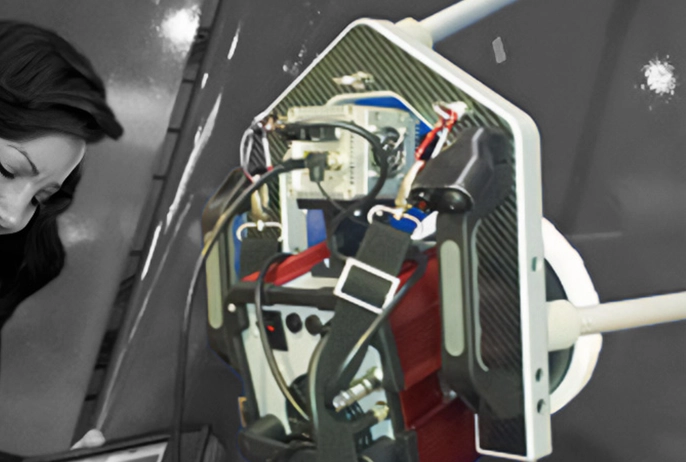

A boroscope is a flexible optical inspection tool that is used in the aerospace sector to visually inspect the interior of hard-to-reach areas in aircraft components, such as engines and airframes. The tool is inserted into the component and can be maneuvered through narrow passages to provide a visual assessment of the condition of the interior of the component.. With automatic scanning, welds and corrosion can be mapped in 2D or 3D, providing a detailed and comprehensive report for analysis and decision-making.

We take pride in building long-term relationships with our clients in the aviation industry, particularly those facing immediate AOG concerns. With a 24-hour direct communication line to the pivotal decision-makers, we’re poised to deliver solutions swiftly and efficiently.

Our processes are conducted with the utmost acute attention to detail, integrity and safety.

aerospace, nondestructive testing, aircraft, composite material, ultrasound, aviation, welding, federal aviation administration, ultrasonic testing, fatigue, corrosion, metal, inspection, engine, eddy current, magnetic particle inspection, radiography, quality assurance, stress, failure, aircraft engine, safety, helicopter, landing gear, fuselage, gas tungsten arc welding, request a quote, magnetism, failure analysis, calibration, fluorescence, as9100, machine, borescope, ultrasonic thickness measurement, laser, gear, phased array, digital image, airbus, measurement, metal fabrication, carbon, cessna, metallurgy, hardness, fastener, jet fuel, fiber, quality management, laboratory, turbine blade, heat, printed circuit board, hydraulic cylinder, aircraft maintenance, sensor, shearography, aluminium, spacecraft, turbine, american society for nondestructive testing, jet engine, astm international, tomography, coating, digital radiography, navigation, materials science, vehicle, certification, gamma ray, aerospace engineering, infrared, knowledge, alloy, dye penetrant inspection, leak, aerospace non destructive testing, aerospace manufacturer, magnet, industrial radiography, radiation, fluorescent penetrant inspection, liquid, magnetic field, dye, steel, particle, metal casting, international space station, visual inspection, electromagnetic field, acoustic emission, wire, evaluation, ultraviolet, pressure, risk, optics, energy, time of flight, frequency, regulatory compliance, nadcap, quality control, oil, neutron, sheet metal, electric current, catastrophic failure, tank, destructive testing, density, ceramic, flux, stainless steel, spectrometer, porosity, ionizing radiation, vibration

aerospace ndt companies, aerospace ndt services, aerospace non destructive testing, aerospace ndt solutions, aircraft ndt, aviation ndt, baron ndt aviation nondestructive testing services, Nondestructive Testing, Nondestructive Inspection, NDT, aircraft ndt inspection

Non-destructive testing (NDT) plays a critical role in ensuring the safety and reliability of aircraft. By detecting flaws and defects in components before they lead to failures, NDT helps maintain the integrity of aviation systems and protects the lives of passengers and crew. Regular NDT inspections are mandated by aviation authorities to comply with safety regulations.

The significance of NDT is underscored by its ability to identify issues that are not visible to the naked eye, such as microcracks or corrosion within critical components. For instance, techniques like ultrasonic testing and radiography can reveal subsurface defects that could compromise the structural integrity of an aircraft, thereby preventing catastrophic failures.

Baron NDT offers tailored non-destructive testing solutions to meet the specific needs of each client. By developing a customized NDT plan, Baron ensures that the appropriate testing methods, frequencies, and personnel are aligned with the unique requirements of different aviation projects. This personalized approach enhances the effectiveness of inspections and optimizes resource utilization.

For example, a customized NDT plan may include a combination of ultrasonic thickness measurements and phased array inspections, depending on the aircraft components involved. This flexibility allows Baron NDT to address varying complexities and challenges faced by clients, ensuring the highest standards of safety and quality are maintained throughout the testing process.

The field of non-destructive testing is continually evolving, with advancements in technology enhancing inspection capabilities. Innovations such as digital radiography and automated ultrasonic testing have improved accuracy and efficiency, enabling faster turnaround times for inspections in the aviation sector. These technologies also facilitate better data analysis and reporting, which are crucial for informed decision-making.

For instance, digital radiography provides high-resolution images that allow for precise identification of defects, while automated systems can increase testing throughput, making it easier for aviation companies to comply with stringent safety regulations. By leveraging these advancements, Baron NDT stays at the forefront of the industry, ensuring clients receive the most effective and reliable testing services available.

Baron NDT prioritizes client engagement by actively involving them in the testing process. From the initial consultation to the final report, clients are kept informed and engaged, ensuring that their specific needs and concerns are addressed. This collaborative approach fosters trust and transparency, essential for long-term partnerships in the aviation industry.

Moreover, Baron NDT provides ongoing support and consultation, helping clients understand the results of inspections and the implications for their operations. This commitment to client service not only enhances customer satisfaction but also contributes to the overall safety and reliability of aviation operations, as clients are better equipped to make informed decisions based on NDT findings.

aerospace, nondestructive testing, aircraft, composite material, ultrasound, aviation, welding, federal aviation administration, ultrasonic testing, fatigue, corrosion, metal, inspection, engine, eddy current, magnetic particle inspection, radiography, quality assurance, stress, failure, aircraft engine, safety, helicopter, landing gear, fuselage, gas tungsten arc welding, request a quote, magnetism, failure analysis, calibration, fluorescence, as9100, machine, borescope, ultrasonic thickness measurement, laser, gear, phased array, digital image, airbus, measurement, metal fabrication, carbon, cessna, metallurgy, hardness, fastener, jet fuel, fiber, quality management, laboratory, turbine blade, heat, printed circuit board, hydraulic cylinder, aircraft maintenance, sensor, shearography, aluminium, spacecraft, turbine, american society for nondestructive testing, jet engine, astm international, tomography, coating, digital radiography, navigation, materials science, vehicle, certification, gamma ray, aerospace engineering, infrared, knowledge, alloy, dye penetrant inspection, leak, aerospace non destructive testing, aerospace manufacturer, magnet, industrial radiography, radiation, fluorescent penetrant inspection, liquid, magnetic field, dye, steel, particle, metal casting, international space station, visual inspection, electromagnetic field, acoustic emission, wire, evaluation, ultraviolet, pressure, risk, optics, energy, time of flight, frequency, regulatory compliance, nadcap, quality control, oil, neutron, sheet metal, electric current, catastrophic failure, tank, destructive testing, density, ceramic, flux, stainless steel, spectrometer, porosity, ionizing radiation, vibration

aerospace ndt companies, aerospace ndt services, aerospace non destructive testing, aerospace ndt solutions, aircraft ndt, aviation ndt, baron ndt aviation nondestructive testing services, Nondestructive Testing, Nondestructive Inspection, NDT, aircraft ndt inspection

Non-destructive testing (NDT) plays a critical role in ensuring the safety and reliability of aircraft. By detecting flaws and defects in components before they lead to failures, NDT helps maintain the integrity of aviation systems and protects the lives of passengers and crew. Regular NDT inspections are mandated by aviation authorities to comply with safety regulations.

The significance of NDT is underscored by its ability to identify issues that are not visible to the naked eye, such as microcracks or corrosion within critical components. For instance, techniques like ultrasonic testing and radiography can reveal subsurface defects that could compromise the structural integrity of an aircraft, thereby preventing catastrophic failures.

Baron NDT offers tailored non-destructive testing solutions to meet the specific needs of each client. By developing a customized NDT plan, Baron ensures that the appropriate testing methods, frequencies, and personnel are aligned with the unique requirements of different aviation projects. This personalized approach enhances the effectiveness of inspections and optimizes resource utilization.

For example, a customized NDT plan may include a combination of ultrasonic thickness measurements and phased array inspections, depending on the aircraft components involved. This flexibility allows Baron NDT to address varying complexities and challenges faced by clients, ensuring the highest standards of safety and quality are maintained throughout the testing process.

The field of non-destructive testing is continually evolving, with advancements in technology enhancing inspection capabilities. Innovations such as digital radiography and automated ultrasonic testing have improved accuracy and efficiency, enabling faster turnaround times for inspections in the aviation sector. These technologies also facilitate better data analysis and reporting, which are crucial for informed decision-making.

For instance, digital radiography provides high-resolution images that allow for precise identification of defects, while automated systems can increase testing throughput, making it easier for aviation companies to comply with stringent safety regulations. By leveraging these advancements, Baron NDT stays at the forefront of the industry, ensuring clients receive the most effective and reliable testing services available.

Baron NDT prioritizes client engagement by actively involving them in the testing process. From the initial consultation to the final report, clients are kept informed and engaged, ensuring that their specific needs and concerns are addressed. This collaborative approach fosters trust and transparency, essential for long-term partnerships in the aviation industry.

Moreover, Baron NDT provides ongoing support and consultation, helping clients understand the results of inspections and the implications for their operations. This commitment to client service not only enhances customer satisfaction but also contributes to the overall safety and reliability of aviation operations, as clients are better equipped to make informed decisions based on NDT findings.