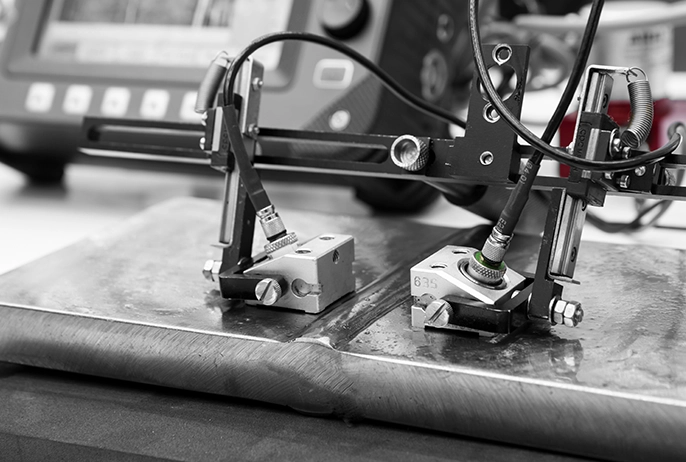

Shear Wave Ultrasonics plays a pivotal role in identifying defects in metallic components, thereby averting possible malfunctions and guaranteeing operational safety. The utilization of Shear Wave Ultrasonics is mandatory for examining complete penetration welds in accordance with various codes, including AWS and ASME.

PAUT Ultrasonics is widely utilized in industrial fabrication processes to inspect welded joints, pipes, pressure vessels, and other critical components for flaws and defects that could compromise their integrity and safety.

Ultrasonic thickness testing is a valuable non-destructive technique commonly used in various industries, including oil and gas, chemical processing, and manufacturing, to measure the thickness of materials such as metal, plastic, and composites without damaging or altering the integrity of the material.

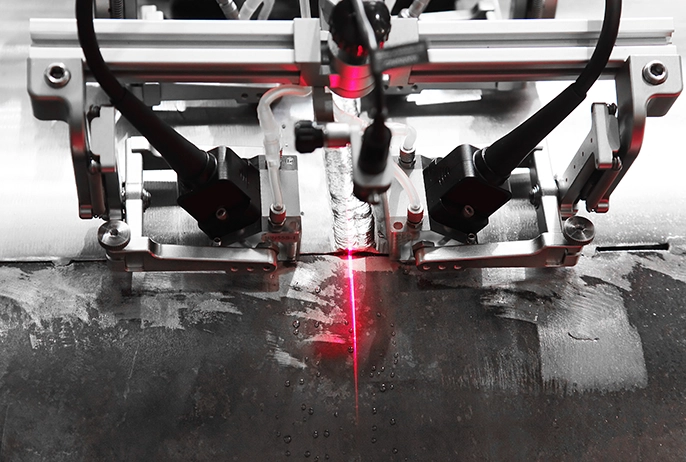

Automatic PAUT scanning is a crucial requirement for compliance with codes such as API 650 and API 653, which govern the construction and maintenance of aboveground storage tanks. The technique provides accurate and efficient inspection of welds and corrosion mapping, ensuring the integrity and safety of the storage tanks. With automatic scanning, welds and corrosion can be mapped in 2D or 3D, providing a detailed and comprehensive report for analysis and decision-making.

High-frequency eddy current inspection is a specialized non-destructive testing technique commonly used in the industrial sector for detecting surface and near-surface defects in materials such as metals, composites, and alloys. In the case of boiler tube inspections, high-frequency eddy current inspection provides highly accurate and efficient detection of defects such as corrosion, erosion, and cracking. The high-frequency signal allows for greater penetration depth, providing more reliable and comprehensive inspection data.

Low-frequency eddy current inspection is a non-destructive testing technique widely used in the industrial sector for detecting subsurface defects in electrically conductive materials such as metals, alloys, and composites. In the case of boiler tube inspections, low-frequency eddy current inspection can accurately detect defects such as pitting, cracking, and wall thinning in the tubes. The low-frequency signal provides greater sensitivity to deeper subsurface defects, making it a valuable technique for inspecting thick-walled components.

This technique utilizes multiple small probes that can be electronically steered to scan a wide area of the material, providing detailed inspection data with high accuracy and resolution. In the case of industrial applications, phased array eddy current inspection is particularly useful for detecting defects in pipes, pressure vessels, and other critical components, including those made of materials with complex geometries or unusual shapes.

Conventional radiography, also known as film radiography, is a widely used non-destructive testing technique in the industrial sector for detecting and examining internal defects in materials such as metals, plastics, and composites.

Computed radiography (CR) using phosphorous imaging plates is a modern non-destructive testing technique that finds extensive application in the industrial sector for inspecting materials such as metals, plastics, and composites. CR using phosphorous imaging plates offers several advantages over conventional film radiography, including faster inspection times, greater flexibility, and the ability to digitally enhance and manipulate images to extract more information.

Digital radiography (DR) is an advanced non-destructive testing technique that utilizes digital detectors to capture and process x-ray or gamma-ray images of materials. DR eliminates the need for film or phosphor plates, providing high-quality, real-time digital images that can be easily stored, retrieved, and shared.

A Portable AC/DC Yoke is a highly effective inspection tool used for Magnetic Particle inspections, a non-destructive testing method used to detect surface and slightly subsurface defects in ferromagnetic materials. This portable inspection tool generates a magnetic field that reveals any surface or slightly subsurface defects.

A large magnetic particle bench, such as ones made by Magnaflux, is a versatile inspection tool used to magnetize components with longitudinal and circular magnetism. This advanced inspection tool generates a magnetic field to reveal surface and slightly subsurface defects in ferromagnetic materials.

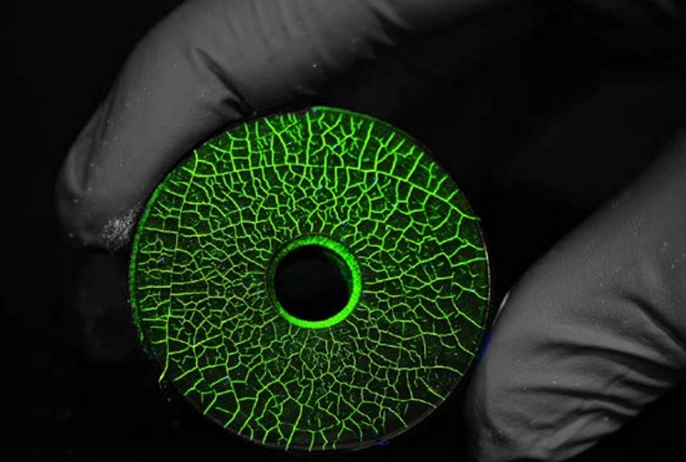

Visible liquid penetrant testing is a commonly used non-destructive testing technique in the industrial sector for detecting surface defects in materials such as metals, ceramics, and plastics. The technique involves applying a visible penetrant to the surface of the material being inspected, allowing it to seep into any surface defects, and then using a developer to draw out the penetrant and make the defects visible.

Fluorescent penetrant testing is particularly useful for detecting small cracks, porosity, and other surface defects in welds, castings, and other components. The fluorescent penetrant provides greater sensitivity than visible penetrants, making it possible to detect smaller defects.

Direct visual testing is a simple and widely used non-destructive testing technique in the industrial sector for detecting surface defects in materials such as metals, plastics, and composites. The technique involves visually inspecting the surface of the material being examined for any signs of cracks, corrosion, erosion, or other surface defects.

Remote visual testing is a non-destructive testing technique that utilizes specialized equipment such as borescopes, fiberscopes, or videoscopes to inspect areas that are difficult to access or are not visible to the naked eye. The technique involves inserting a flexible, remote device into the area being inspected, which transmits images back to a monitor or recording device.

Hardness testing is a commonly used inspection technique for assessing the mechanical properties of critical components and structures. This inspection method involves using specialized tools, such as the UCI and Leeb rebound testers, to measure the hardness of materials and detect any areas of excessive wear or stress that may compromise the integrity of the component.

X-ray fluorescence (XRF) works by exposing a material to a high-energy beam of X-rays, which causes the atoms in the material to emit fluorescent X-rays. The energies of these X-rays are characteristic of the elements present in the material, allowing XRF to identify the chemical composition of the material.

By measuring changes in the electrical conductivity of the material, inspectors can determine whether the material has been damaged by heat, which is a common cause of failure in piping system.

Our focus on building long-term relationships with industrial clients is what sets us apart, enabling us to deliver tailored solutions that meet the unique needs and challenges of each individual customer.

Our processes are conducted with the utmost acute attention to detail, integrity and safety.

nondestructive testing, ontario, open access, phased array, welding, inspection, ultrasonic testing, disease, evaluation, certification, aviation, aircraft, agency, award, nov, cessna, heat, leak detection, pipeline, leak, borescope, ultrasound, videoscope, sensor, pipe, measurement, unmanned aerial vehicle, image resolution, construction, infrared, metal, machine, energy, corrosion, steel, visual inspection, fossil fuel, optics, oil, accuracy and precision, tank, radiography, aerospace, mining, usb, calibration, electron, acoustics, wind turbine, ultrasonic thickness measurement, pressure, infrastructure, laser, duct, storage tank, coating, automotive industry, engine, mobile device, field of view, eddy current, magnetic particle inspection, image sensor, diameter, voltage, magnet, optical fiber, endoscope, indoor air quality, fiberscope, wind, carbon dioxide, magnetic flux leakage, electromagnetic acoustic transducer, frequency, wire, transport, humidity, downtime, ultraviolet, radiation, natural gas, industrial radiography, quality assurance, stainless steel, turbine, cement, digital camera, quality control, transmission, chimney, duct cleaning, magnetic field, automation, nuclear power plant, fluorescence, acoustic emission, nuclear power, volatile organic compound, gas leak, carbon, safety, high voltage, dye penetrant inspection, depth of field, angle, led lamp, condition monitoring, porosity, rechargeable battery, digital image, sd card, asset, concrete, multispectral imaging, efficiency, power station, simultaneous localization and mapping, length, magnetic flux, memory card, transducer, battery pack, data logger, surveying, lidar, heat exchanger, carbon monoxide, copper, alloy, flux, computer vision, wavelength, particle, laboratory, instrumentation, moisture, compressed air, confined space, compressor, digital radiography, visibility, dust, vehicle, electromagnetic radiation, navigation, naked eye, plastic, electromagnetism, hdmi, semiconductor, polymer, research, human eye, corrosion monitoring, warranty, autofocus, interface, payload, backlight, iron, customs, powder, gear, predictive maintenance, innovation, touchscreen, 3d modeling, diode, ergonomics, ship, sampling, boiler, data analysis, parameter, combustion, noise, joystick, level of detail, high frequency, aerospace manufacturer, composite material, fatigue, aircraft maintenance, spacecraft, helicopter, shearography, federal aviation administration, request a quote, american society for nondestructive testing, aluminium, jet engine, airworthiness, destructive testing, fluorescent penetrant inspection, fuselage, regulatory compliance, liquid, aviation safety, regulation

industrial hvac ndt inspection tool, baron ndt, industrial ndt, industrial ndt services, ndt in florida, ndt inspection company florida, ndt services florida, baron ndt services, aerospace ndt services, baron ndt aviation nondestructive testing services, nondestructive testing vendors long cable lengths deep tanks vessels, aerospace ndt companies, aerospace ndt, Nondestructive Testing, Nondestructive Inspection, NDT, aerospace ndt inspection services

Advanced non-destructive testing (NDT) techniques are essential for ensuring material integrity in complex industrial applications. These methods go beyond traditional testing approaches, allowing for more precise and comprehensive inspections of components that are critical to operational safety.

Techniques such as phased array ultrasonics and computed radiography enable inspectors to detect minute flaws and assess the internal structure of materials without causing any damage. These advanced methods are increasingly adopted in sectors like aerospace and nuclear, where safety standards are exceptionally high.

Regular non-destructive testing inspections provide numerous benefits, including enhanced safety, reduced downtime, and increased lifespan of equipment. By identifying potential failures before they occur, companies can prevent accidents and costly repairs, ensuring operational efficiency.

Moreover, regular NDT inspections can help in maintaining compliance with industry regulations and standards, which is crucial for avoiding legal penalties. For instance, industries like oil and gas benefit significantly from routine inspections, as they mitigate risks associated with hazardous materials and environments.

Case studies highlight the effectiveness of non-destructive testing in various industrial applications. These real-world examples illustrate how companies have successfully implemented NDT to enhance safety protocols and improve operational efficiency.

For instance, a major oil refinery utilized ultrasonic testing to detect corrosion in pipelines, which resulted in significant cost savings and prevented potential environmental hazards. Such case studies not only showcase the practical benefits of NDT but also serve as a valuable reference for industries considering these techniques.

Selecting the appropriate non-destructive testing method is crucial for achieving accurate results tailored to specific industrial requirements. Factors such as material type, component geometry, and the nature of potential defects must be considered when making this decision.

For example, ultrasonic testing is ideal for detecting internal flaws in metals, while visual inspections are effective for surface defects. Understanding the strengths and limitations of each method enables businesses to optimize their inspection processes and ensure the reliability of their assets.