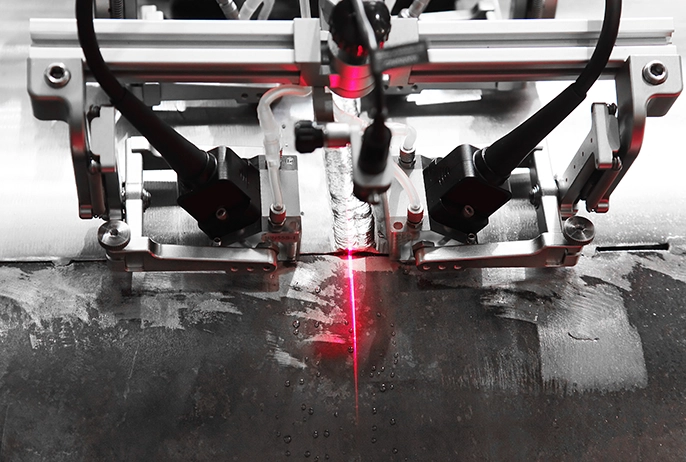

Advanced NDT plays a critical role in modern inspection, revolutionizing how we approach defect detection and material analysis. In the fast-evolving world of non-destructive testing, innovation is not just a competitive advantage—it’s a necessity. At Baron NDT, we pride ourselves on staying at the forefront of technology, pushing the boundaries to ensure precision, reliability, and efficiency in our services. As industries demand more from NDT, we meet the challenge with state-of-the-art advancements, ensuring safety and quality in every application.

The Role of Advanced NDT in Defect Detection

Recent innovations have transformed defect detection and material analysis. Techniques such as automated defect detection in digital radiography—powered by deep learning—are setting new standards for accuracy and efficiency. These advancements minimize the limitations of manual inspections, such as human error and time consumption, while increasing the reliability of identifying critical flaws in high-stakes industries like aerospace, automotive, and construction.

For example, integrating machine learning algorithms with traditional NDT methods allows us to analyze large datasets efficiently. By leveraging deep learning models, Baron NDT can identify minute defects in complex components—whether it’s a micro-crack in an aerospace weld or a cavity in critical infrastructure materials. Learn more about phased array ultrasonic inspection for advanced pipeline testing.

How Baron NDT Leads the Way

Baron NDT doesn’t just adopt new technology; we innovate with it. Our approach includes:

- Advanced Digital Radiography Systems: Utilizing high-resolution digital detectors and imaging techniques to ensure clarity and precision in defect detection.

- AI-Driven Analysis: Through research partnerships and in-house development, we build machine learning models trained to recognize defects with unparalleled accuracy.

- Data Augmentation: Simulating a range of defect scenarios using advanced software to create robust models that perform reliably in challenging environments.

- Real-World Application: Field-testing our systems under rigorous conditions to ensure they meet industry standards and exceed client expectations.

The Benefits of Advanced NDT for Our Clients

Adopting the latest technology isn’t just about being cutting-edge—it’s about delivering tangible benefits to our clients. Here’s how Baron NDT’s innovative approach translates to value:

- Increased Inspection Reliability: Reducing false positives and improving detection rates so that only relevant defects are flagged, saving time and resources.

- Enhanced Safety Standards: Accurate detection minimizes the risk of structural failures and ensures compliance with the most stringent safety requirements. See standards from the American Society for Nondestructive Testing (ASNT) for industry best practices.

- Cost Efficiency: Automation and advanced analytics reduce inspection times and labor costs, providing savings that we pass on to our clients.

- Future-Proof Solutions: Designing our technology to adapt and evolve, ensuring long-term relevance and value.

Partnering for the Future

Innovation is a journey, not a destination. At Baron NDT, we continuously invest in research, technology, and talent to stay ahead of the curve. As the industry moves toward more automated and intelligent systems, we are committed to leading the way and delivering excellence in every project.

Join us as we redefine the standards of NDT, one innovation at a time. Contact Baron NDT today to learn how we can elevate your inspection processes with our cutting-edge solutions.