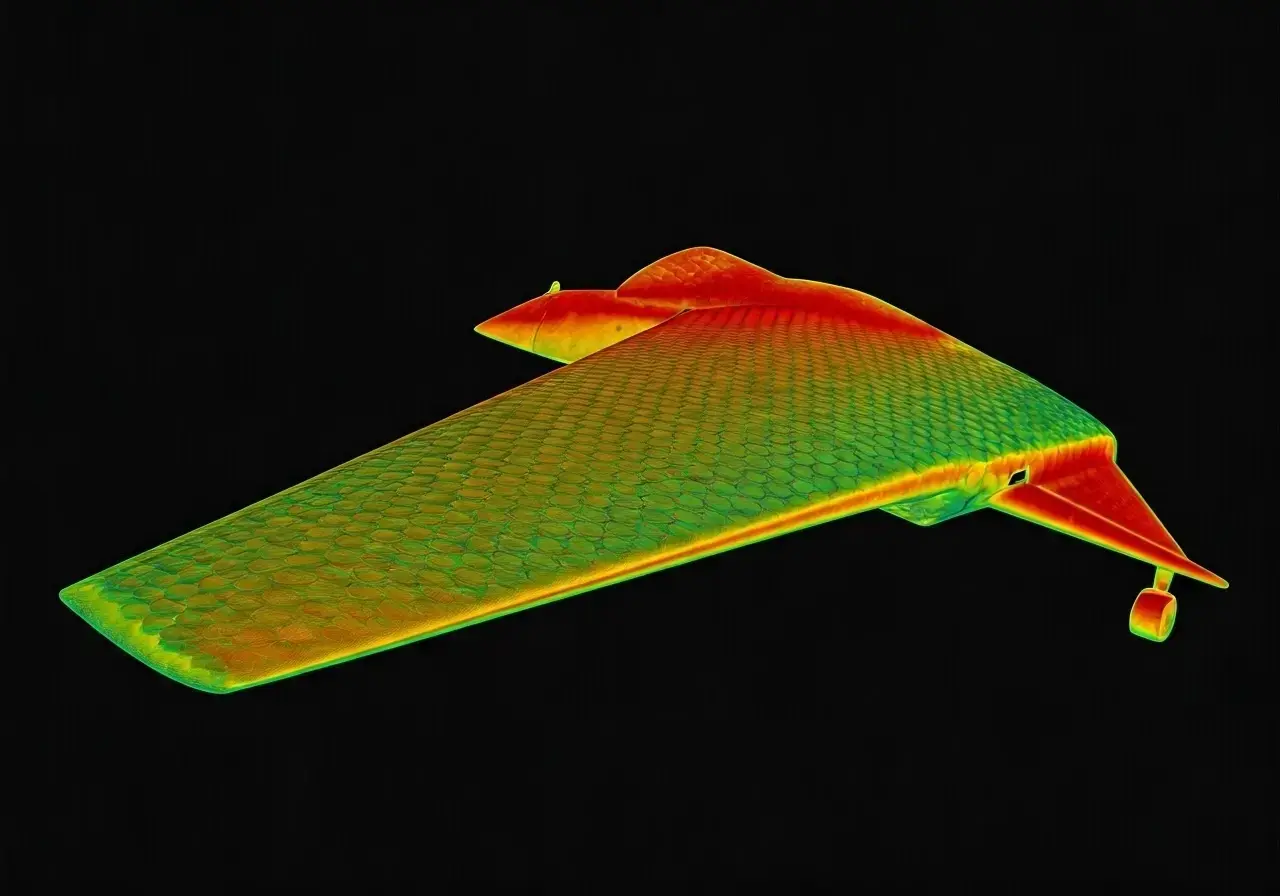

Thermography inspection Airbus rudder NDT revolutionizes aviation safety through advanced thermal imaging technology. Additionally, this cutting-edge approach detects structural defects in critical flight components with unprecedented precision. Furthermore, aerospace professionals recognize this method as the gold standard for non-destructive testing in modern aircraft maintenance.

What Makes Thermography Essential for Aircraft Safety?

Infrared thermography delivers precise temperature mapping of Airbus rudder components. Moreover, technicians identify potential failures before they compromise flight safety. Similarly, this technology reduces aircraft downtime significantly compared to traditional inspection methods.

Modern Airbus aircraft utilize composite materials extensively in rudder construction. However, these materials present unique inspection challenges that conventional NDT methods struggle to address. Consequently, thermography inspection Airbus rudder NDT provides the optimal solution for detecting hidden structural anomalies.

Benefits of Thermography Inspection for Airbus Rudder NDT

Rapid assessment capabilities distinguish thermography from other inspection techniques. Initially, thermal cameras capture comprehensive rudder surface data within minutes. Subsequently, analysis software identifies temperature variations indicating structural defects instantly.

Cost-effectiveness drives widespread adoption of this technology across the aviation industry. Furthermore, thermography eliminates the need for component disassembly during routine inspections. Therefore, maintenance teams complete thorough evaluations without extensive aircraft downtime.

- Early detection prevents catastrophic component failures

- Non-invasive analysis preserves component integrity

- Real-time results accelerate maintenance decision-making

- Comprehensive coverage ensures no defects escape detection

How Thermography Detects Rudder Component Issues

Temperature variations reveal hidden structural problems invisible to conventional inspection methods. Initially, thermal cameras detect heat signatures across entire rudder surfaces. Subsequently, specialized software analyzes thermal patterns to identify defect locations precisely.

Delamination detection represents a primary application of this technology. Additionally, moisture ingress identification prevents long-term structural degradation. Furthermore, impact damage assessment ensures flight safety through comprehensive component evaluation.

Baron NDT services specializes in advanced thermographic inspection techniques for aerospace applications. Moreover, our certified technicians deliver accurate results that exceed industry standards consistently.

Comparison with Traditional NDT Methods

Ultrasonic testing requires physical contact with component surfaces. However, thermography inspection Airbus rudder NDT operates contactlessly from safe distances. Consequently, this approach eliminates contamination risks while maintaining inspection accuracy.

Visual inspection methods detect only surface-level defects effectively. Conversely, thermal imaging penetrates composite materials to reveal subsurface anomalies. Therefore, thermography provides comprehensive structural assessment capabilities unmatched by conventional techniques.

Implementation in Modern Aircraft Maintenance

Airlines integrate thermography into routine maintenance schedules effectively. Initially, technicians perform baseline thermal surveys during aircraft delivery inspections. Subsequently, periodic assessments track component condition changes over operational lifespans.

Predictive maintenance strategies rely heavily on thermographic data analysis. Furthermore, maintenance teams schedule component replacements based on thermal trend analysis. Consequently, this proactive approach prevents unexpected failures while optimizing maintenance costs.

For comprehensive insights into aviation NDT best practices, explore our related NDT blog covering industry innovations and technical developments.

Quality Assurance and Certification Standards

Regulatory authorities mandate specific thermographic inspection protocols for commercial aircraft. Additionally, technicians must maintain current certifications in thermal imaging analysis techniques. Furthermore, equipment calibration ensures measurement accuracy throughout service intervals.

Documentation requirements demand detailed thermal imaging reports for each inspection cycle. Moreover, these records support aircraft airworthiness certification processes. Similarly, trend analysis facilitates proactive maintenance planning based on historical thermal data.

Future Developments in Thermal Imaging Technology

Artificial intelligence integration enhances automated defect recognition capabilities significantly. Initially, machine learning algorithms analyze thermal patterns more accurately than human operators. Subsequently, these systems provide consistent interpretation results regardless of technician experience levels.

Advanced sensor technology delivers higher resolution thermal imaging with improved sensitivity. Furthermore, portable equipment enables field inspections without hangar requirements. Therefore, maintenance flexibility increases while maintaining inspection quality standards.

Thermography inspection Airbus rudder NDT continues evolving through technological advancement and regulatory refinement. Ultimately, this technology ensures aviation safety through precise, reliable, and efficient structural component assessment capabilities that protect passengers and aircraft worldwide.